MAG-CX3, a vertical CNC milling machine

MAG-CX3 500

Accuracy and reliability at your service

MAG-CX3 500, the vertical CNC machine, allows you to carry out high-precision and repeatable mechanical machining.

Constructed with a solid and tested aluminium frame, it is the ideal machine for both industrial and non-industrial mechanical productions.

Equipped with four wheels, it can be easily moved around when needed, or stored after its use.

The total absence of mechanical play makes the MAG-CX3 perfect for dealing with different types of works, from aluminium milling to extremely precise engraving on precious materials.

MAG-CX3 is equipped with a nebulization system for machining – consisting of a reservoir and a nebulizer – as well as a PC with a jointed arm.

TECHNICAL HIGHLIGHTS

MAG-CX3 is precise and adaptive to any type of processing

Granite Base

Mechanical movement

Probe for Z axis calibration

Hybrid motors

Pneumatically operated tool

4th rotary axis

ATC three-phase brushless electro spindle

Spindle for 4th axis

Smart concept of milling

Developed for Accuracy

Reliable machining

Versatile milling

real - time verification

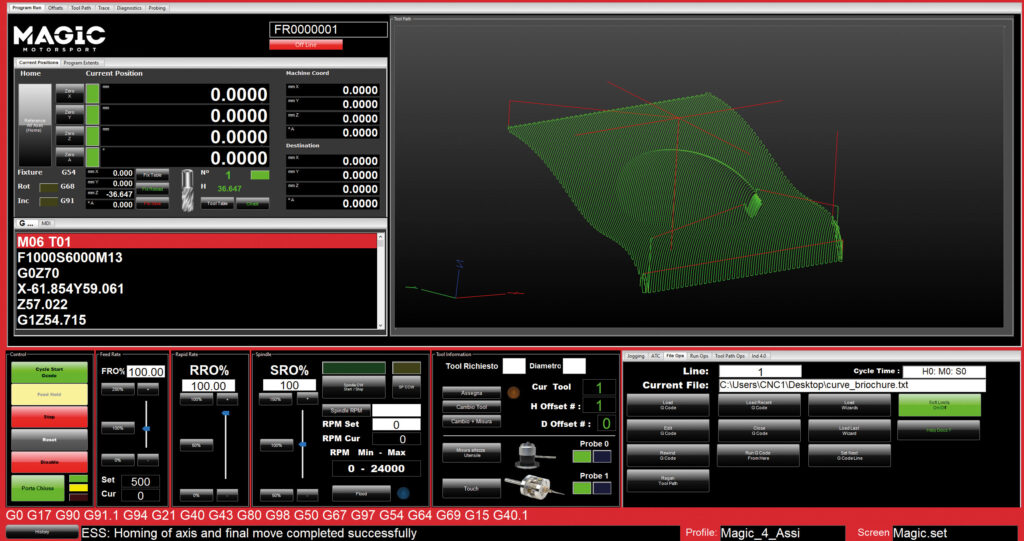

Intuitive and easy-to-use software

The MAG-CX 3 500 control software has been developed to guarantee an optimized management of the CNC machine. The graphical interface fits the criteria for simplicity of use, aiming at simplifying and improving the user experience.

Connected and intuitive, the interface allows the user to set specific data according to the CNC operator’s needs as well as to record the main technical values of the machine for work reports or malfunctions.

Everything has been engineered and assembled in Italy, including the software: an in-house system made to facilitate professional work.

Join Our Newsletter

Sign up to our newsletter and get MAG-CX3 brochure as well as all the latest updates on how we can help your business grow. Keep up with the new features and design innovations of MAG-CX3 500!

MAG-CX3 500

Data Sheet

| Machine type | Vertical CNC milling machine |

| Floor space | 1620 mm x 1010 mm |

| Max height | 2040 mm |

| Weight | 720 kg |

| X probe axis | 485 mm |

| Y probe axis | 325 mm |

| Z probe axis | 190 mm |

| Number of axis | 3 + 1 |

| Precision | ± 0.01 mm |

| Type of spindle | ATC |

| Maximum spindle speed | 30000 rpm |

| Maximum interpolated speed | 10000 mm/min |

| Maximum absorbed power | 3 kW |

| Voltage | 220 V |

| Motor type | Hybrid closed loop |

| Motor torque | 12 Nm |

| Movement | Ball screw |

| Automatic tool change | Pneumatic handling |

| Pneumatic operating pressure | 6 - 8 bar |

| 6-position tool change | 6 |

| Type of cones | ISO 20 - ER20 |

| PC Specifications | Ryzen 5 4500U - 16 Gb DDR4 - 512 SSD |

| Workable materials | Aluminum, Copper, Brass, Bronze, Polycarbonate, Plexiglass, Delrin, ABS, Acrylic |

Choose how to customize your MAG-CX3!

CONTACT US

Get a quote

You’re just a few steps away from your tailor-made CNC machine: tell us your needs, we’ll customize it for you!